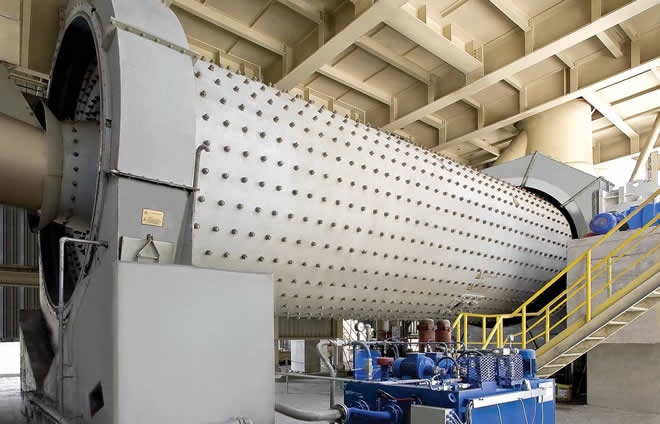

A cement mill is a type of ball mill used to grind materials into fine powder. It is employed for grinding cement, limestone, gypsum, fly ash, clinker, bauxite, and similar substances. The complete cement milling plant comprises a ball mill, bucket elevator, air classifier, screening machine, and other components.

Application fields:

cement, silicate, new construction materials, refractory materials, chemical fertilizer, black and non-ferrous metal dressing, glass and ceramics industries.

Adapted material:

fly ash, limestone, quartz, aluminum powder, coal powder, steel slag, ore, potash feldspar, iron ore, iron slag, aluminum slag, silicon carbide, alumina, coal gangue, etc.

whatsApp

whatsApp