1.Mining and mineral processing

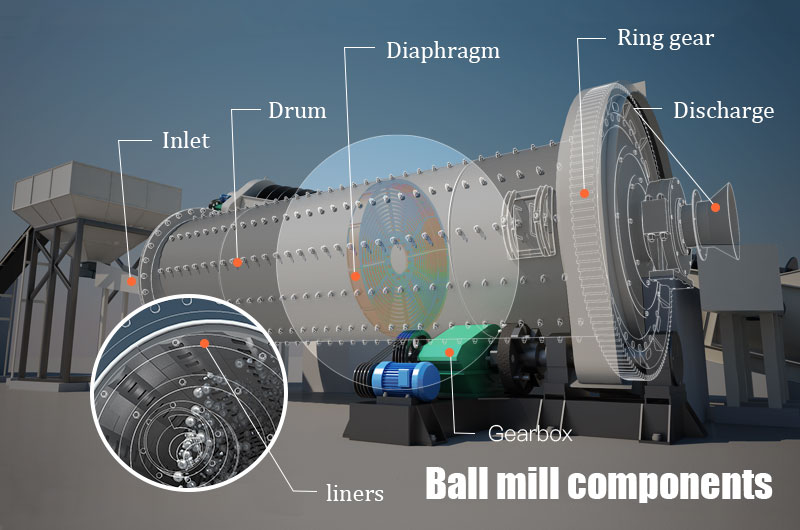

Ball mills are widely used in the grinding process of various metal ores, including gold ore, copper ore, iron ore, silver ore, zinc ore, tungsten ore, and lead ore. By reducing ore particle size, valuable minerals can be extracted more effectively.

Additionally, ball mills are used to grind materials like bentonite, kaolin, barite, and talc. In ore processing, ball mills typically work alongside crushers, flotation machines, magnetic separators, and gravity separators.

2.Cement grinding

Cement ball mills are mainly used to grind clinker and gypsum into fine powder for cement production. They can also be used to grind materials like slag, pozzolana, dolomite, and fly ash, which are added to cement to improve its strength and durability.

3.Fertilizer production

In fertilizer production, ball mills are used to grind raw materials like phosphate rock and limestone into fine powder, and to effectively mix materials like urea and ammonium nitrate, enhancing the quality of the fertilizer product.

Ball mills are also widely used for grinding coal, coke, construction materials, glass, silica sand, marble, and other materials.

4.Ceramics production

In the ceramics industry, ball mills are used to grind ceramic raw materials, such as feldspar, quartz, and clay. The finely ground materials can form a more uniform slurry, leading to ceramic products that are more consistent and durable.

In addition to grinding, ball mills are also used for mixing, stirring, and dispersing materials. They are popular in industries such as chemicals, pharmaceuticals, and food processing.

whatsApp

whatsApp