A lime kiln (also known as an active lime kiln) is the core equipment for calcining active lime and lightly burned dolomite used in iron and steel plants, ferroalloy plants, calcium carbide plants, and magnesium metal plants.

Cement kilns mainly use clinker for calcification, which can be divided into dry cement kilns and wet cement kilns. The lime rotary kiln production line constitutes a process system that converts limestone (primarily composed of calcium carbonate, CaCO₃) into quicklime (calcium oxide, CaO) through high-temperature calcination. Key equipment includes a vertical preheater, conveying chute, rotary kiln, cooler, and multi-channel pulverised coal combustion unit. The entire lime rotary kiln production line features high automation, enhanced labour productivity, and superior lime product quality, representing an advanced production framework within the active lime manufacturing sector. This technology finds extensive application across industries including construction, metallurgy, chemical processing, and agriculture.

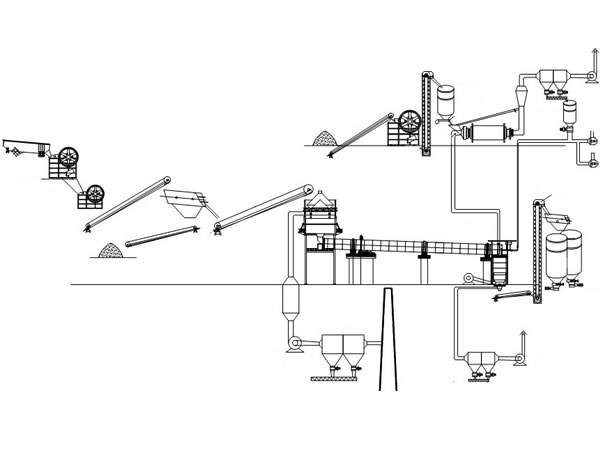

1.Raw Material Pre-treatment:

Limestone undergoes coarse crushing via a jaw crusher, followed by fine crushing in an impact crusher. The process then screens the qualified aggregate through a vibrating screen.

2.Preheating and Calcination:

The process involves preheating qualified aggregate to 600–800°C in a vertical preheater and then conveying it into a rotary kiln for high-temperature calcination to produce quicklime.

3.Cooling and Finished Product:

The high-temperature quicklime enters a cooler, which cools it to below 100°C before a conveying system transfers it to the finished product silo for storage. The process for slaked lime production requires an additional hydrator to react the quicklime with water, producing calcium hydroxide.

4.Environmental Treatment:

Flue gas generated during calcination is purified through a dust collector before discharge. Collected dust is returned to the production line for reuse.

whatsApp

whatsApp