Zhongya kaolin rotary kiln production line is primarily employed for the high-temperature calcination of kaolin, thereby removing crystalline water, eliminating organic matter, enhancing whiteness and purity, and altering its physicochemical properties. This production line yields high-value-added products widely utilised in the paper, coatings, and rubber industries, renowned for their high whiteness, exceptional stability, and superior physical properties.

The Zhongya kaolin rotary kiln production line utilizes high-temperature calcination to remove crystalline water, eliminate organic matter, enhance whiteness and purity, and alter the physicochemical properties of kaolin. Zhongya Machinery's kaolin rotary kiln production line yield high-value-added calcined kaolin products suitable for applications in papermaking, coatings, rubber, and high-grade ceramics.

1.Raw Material Preparation and Feeding

The preceding processes (such as crushing, classification, and drying) produce powdered kaolin raw material meeting specified moisture and particle size requirements.A screw conveyor transports the raw material to the hopper at the kiln tail. Material is then steadily and uniformly fed from the hopper into the rotary kiln.

2.Calcination Process

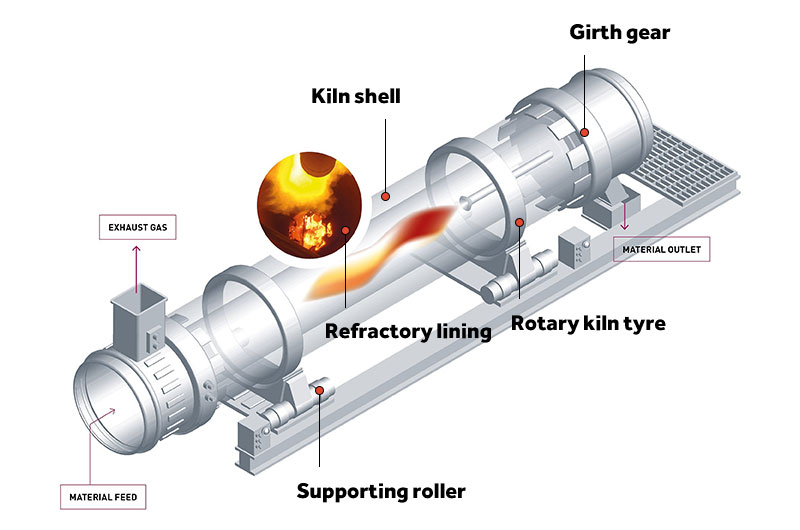

The rotary kiln is driven by the transmission mechanism, which causes it to rotate continuously at a slow pace. This rotation, in turn, causes the raw material within the cylinder to tumble and advance forward. Burners are located at the head of the kiln. They are typically fuelled by natural gas, diesel, or coal gas. These burners project high-temperature flames to establish a stable thermal field. The kiln's inclination angle and rotational speed collectively determine the material's residence time. Therefore, controlling these parameters is essential to ensure complete calcination.

3.Discharge and Quenching

The fully calcined kaolin is discharged from the kiln head and falls into a dedicated cooler (such as a single-drum cooler or cyclone cooler). The cooler rapidly cools the superheated material by blowing ambient air or forced cooling air onto it. This step fixes the calcined crystal structure, prevents product ‘yellowing’ and maintains high reactivity.

4.Exhaust Gas Treatment and Waste Heat Utilisation

An induced draught fan extracts high-temperature exhaust gas from the kiln tail. The exhaust gas first enters the preheater, transferring part of its heat to the incoming cold raw materials to enhance thermal efficiency. Subsequently, the exhaust gas passes through a bag filter or electrostatic precipitator, removing the vast majority of the dust it carries. The system finally discharges the purified exhaust gas through the chimney in compliance with standards.

5.Product Collection and Packaging

The cooled calcined kaolinite product is conveyed by transport equipment into the finished product silo.

- Outstanding Product Advantages:

The production line employs precise temperature-controlled calcination to consistently yield high-quality calcined kaolinite products characterised by exceptional whiteness, purity, and chemical stability.- Exceptionally High Thermal Efficiency:

The system incorporates highly efficient waste heat recovery units, enabling direct utilisation of kiln tail gas heat for raw material preheating, significantly reducing overall fuel consumption.- Environmentally Sound Production Process:

An integrated exhaust gas treatment system effectively purifies and ensures compliant emissions, whilst recovered dust is returned to the process, achieving clean production.- High Degree of Automation:

A centralised control system automatically monitors and adjusts critical parameters throughout, ensuring continuous, stable production and consistent product quality.

whatsApp

whatsApp