Gold mining equipment is mainly used for separating gold ore in mineral processing industry, and the methods of processing gold ore are flotation, magnetic separation and re-election. Gold mining equipment mainly includes jaw crusher, ball mill, classifier, flotation machine, dryer, gold shaking table, spiral concentrator and so on.

Gold Flotation Production Line is a widely employed method for processing rock gold in gold ore processing plants, frequently utilised for treating easily floatable gold-bearing sulphide minerals. The Gold Flotation Production Line maximises the concentration of gold within sulphide minerals, with tailings being directly discarded, resulting in low operational costs for the processing plant. The flotation process primarily comprises the following steps: feeding, mixing, filling, and frothing.

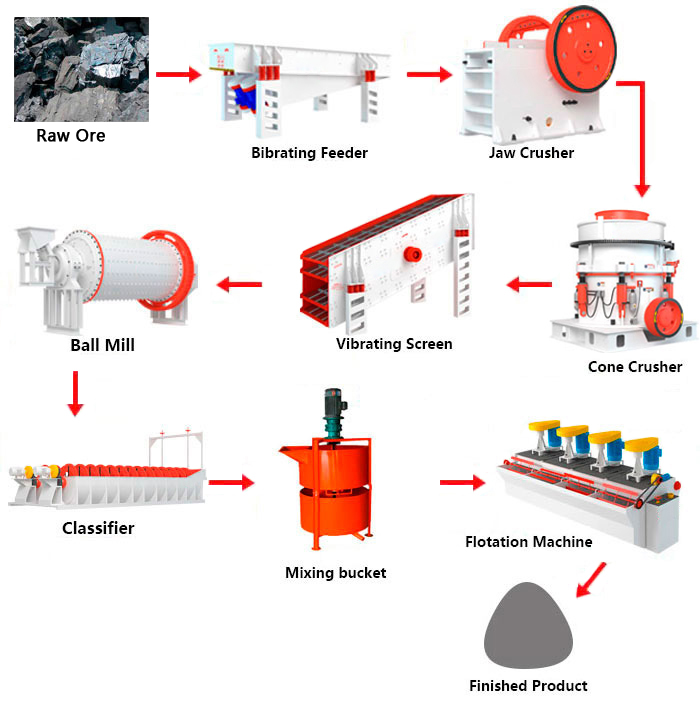

1:Crushing

The loader feeds the raw ore into the vibrating feeder, and the vibrating feeder feeds the material evenly into the jaw crusher for the preliminary crushing process. If required, a cone crusher or hammer crusher can perform secondary crushing to produce properly sized particles.

Required equipment; vibrating feeder, jaw crusher, cone crusher or hammer crusher

2:Grinding

The crushed material passes through the vibrating screen into the ball mill, through the mill for fine treatment

Required equipment: ball mill, spiral classifier

3:Separation

Gold Ore Flotation: The flotation machine receives the slurry, mixes it with added chemicals, and agitates the mixture to extract the valuable ore powder. In the flotation process, the slurry is aerated through agitation. This causes target mineral particles to attach selectively to the rising air bubbles. Mineral-laden bubbles form a froth on the slurry surface, and operators then skim off this froth as concentrate. The beneficiation process then discharges the remaining slurry, which contains the unwanted material, as tailings. This achieves the mineral separation.

Required equipment: flotation machine

4: Drying

the obtained gold powder is fed into the desiccant for drying to get the required material.

The selection and combination of equipment are critical in the gold beneficiation process. These decisions depend on several factors, including the nature of the gold ore, the specific beneficiation process, and the production scale. In practical applications, engineers select and configure equipment based on specific conditions to optimize beneficiation efficiency and economic returns.

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp