The cement rotary kiln serves as the primary equipment in both dry and wet process cement clinker production lines, chiefly employed for calcining cement clinker.

Zhongya Cement production line is widely applied to process soft or medium hard stone such as limestone, gypsum, marble, calcite, dolomite and etc.). size of raw materials can range from 500mm to 5mm. It employs high-temperature rotation to heat raw materials such as limestone, clay, and other auxiliary materials, thereby producing high-quality cement clinker.The Zhongya cement production line can process these materials into aggregate for use in construction projects. Built on our rich experience, you can rely on Zhongya Machinery for a complete cement rotary kiln production line that delivers low energy consumption, low investment cost, easy maintenance, and high efficiency.

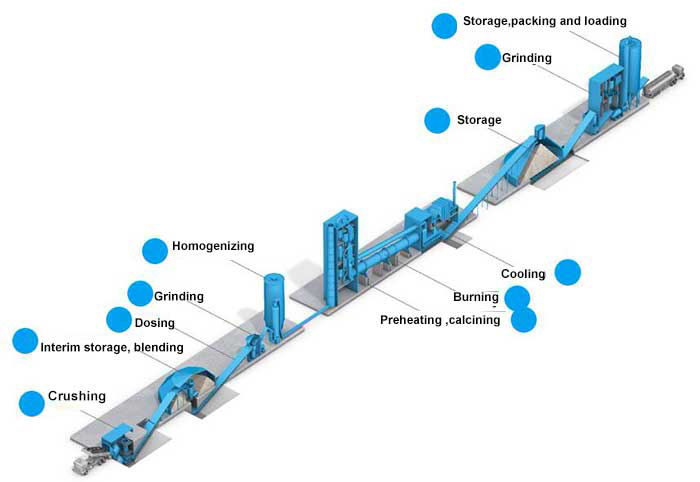

1.Crushing and Homogenisation:

Large lumps of limestone and other raw materials are first crushed into smaller pieces, then spread evenly across the stockyard to ensure consistent composition.

2.Raw Material Grinding:

The process feeds the mixed raw materials into large vertical mills, which then grind them into an extremely fine powder. Simultaneously, the hot waste gases from the kiln tail dry the material, achieving two objectives at once. This finished product is known as ‘raw meal powder’.

3.Preheating and Precalcination:

The raw meal powder first enters the preheater and precalciner. Here, the materials rapidly heat to approximately 900°C, where the majority of decomposition reactions occur.

4.Rotary Kiln Calcination:

The precalcined material then enters the rotary kiln. Here, heated to approximately 1450°C, the material partially melts, undergoes chemical reactions, and ultimately sinter into small, black, glassy spheres known as cement clinker.

5.Cooling:

The red-hot clinker immediately enters a grate cooler, where a blast of cold air rapidly cools it. This process ensures the clinker retains high reactivity while recovering substantial heat for reuse within the system, making it highly energy-efficient.

6.Blending:

The process proportionately mixes the cooled clinker with gypsum (to regulate cement setting time) and blends it with materials (such as fly ash, which enhances performance and reduces costs).

7.Cement Grinding:

The process feeds the blended mixture into cement mills, which grind it into an extremely fine powder—the cement we ultimately use.

whatsApp

whatsApp