Stone Crusher And Sand Making Plant

Capacity: 80-100 tonnes/hour (granite, basalt and other hard rocks)

Feed size: ≤800mm (larger feed opening can be customised)

Discharge size: 0-5mm (mechanism sand), 5-10mm, 10-20mm, 20-31.5mm (adjustable)

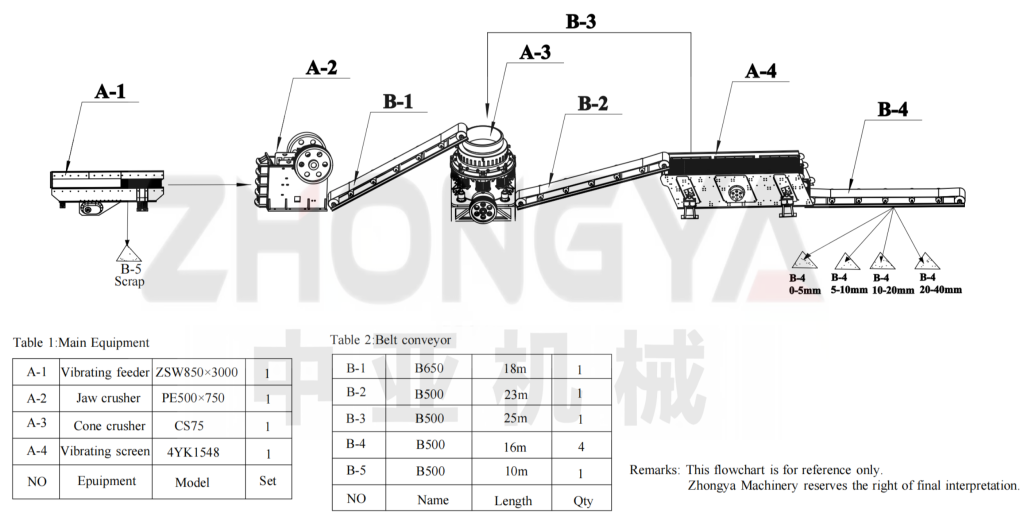

80-100 tph Hard stone crushing plant is including Hopper, vibrating feeder , jaw crusher , cone crusher, vibrating screen, belt conveyor. It can primarily involved in the crushering of aggregates (coarse aggregates, crusher run, rock sand, fine aggregates) from limestone, granite, andesite,etc. Coarse aggregates are usually used in ready mix concrete and asphaltic concrete. Builders use crusher run for road bases and sub-bases, and fine aggregates for concrete and plastering.

1.Raw stone in higher or medium hardness is fed into jaw crusher through vibrating feeder. Vibrating feeder with grate bars is optional to separate stone debris or soil in advance.

2.After primary jaw crusher, the material will go to PYB cone crusher, or CS cone crusher, or hydraulic cone crusher or fine jaw crusher for secondary crushing by belt conveyor.

3.The final crushed material goes to vibrating screen to classify final qualified products according to different size ranges as stock pile forsale, or for road builidng use. The system (or operators) will return unqualified materials to the stone crushing equipment for recrushing.

4.Customer can classify final products according to different size ranges. All the final products are up to the related standards within and beyond China. Dust is generated during the working process while the dust control units are needed.

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp