Stone Crusher And Sand Making Plant

Capacity: 180-220 tonnes/hour (granite/basalt)

Feeding size: ≤800mm (1000mm super-large can be customised)

Finished specification:0-5mm /5-10mm/10-20mm/20-30mm (adjustable)

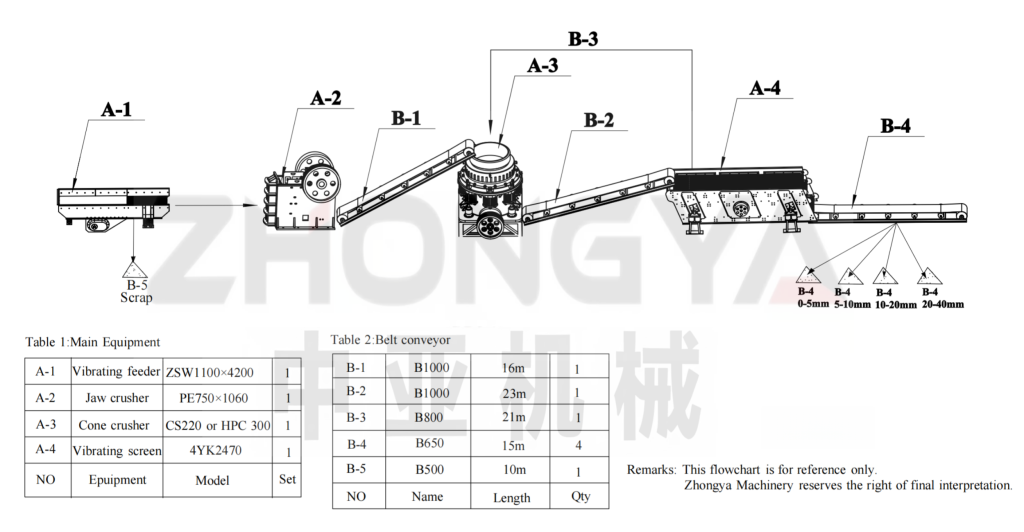

180-220 tph Stone Crusher Plant is a stationary stone crushing and screening plant. 180-220 tph Stone Crusher Plant could be customized to two stage crushing process or three stage crushing plant. The main machines includes: jaw crusher , cone crusher , or impact crusher, vibrating screen and belt conveyors. It could manufacture of aggregates (coarse aggregates, crusher run, rock sand, fine aggregates) from limestone, granite, andesite, etc. Builders typically use coarse aggregate for ready-mixed concrete and asphalt concrete.Construction crews use crushed material for road base and subbase. Workers utilize fine aggregate to produce concrete and plaster."

1.Feeding:The excavator pours the raw materials into the silo, and the vibrating feeder evenly transports them to the jaw crusher.

2.Coarse crushing stage:The jaw crusher crushes the raw materials to ≤150mm, and transports them to the transfer yard or directly to the medium crushing through a belt conveyor.

3.Fine crushing stage:The cone crusher further crushes the coarse aggregate to produce the materials we want. After screening, the oversized materials return to the cone crusher.

4.Screening and finished product classification:The vibrating screen divides the materials into 4 specifications:0-5mm (machine-made sand), 5-10mm (fine aggregate), 10-20mm (medium aggregate), 20-40mm (return to crushing)

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp