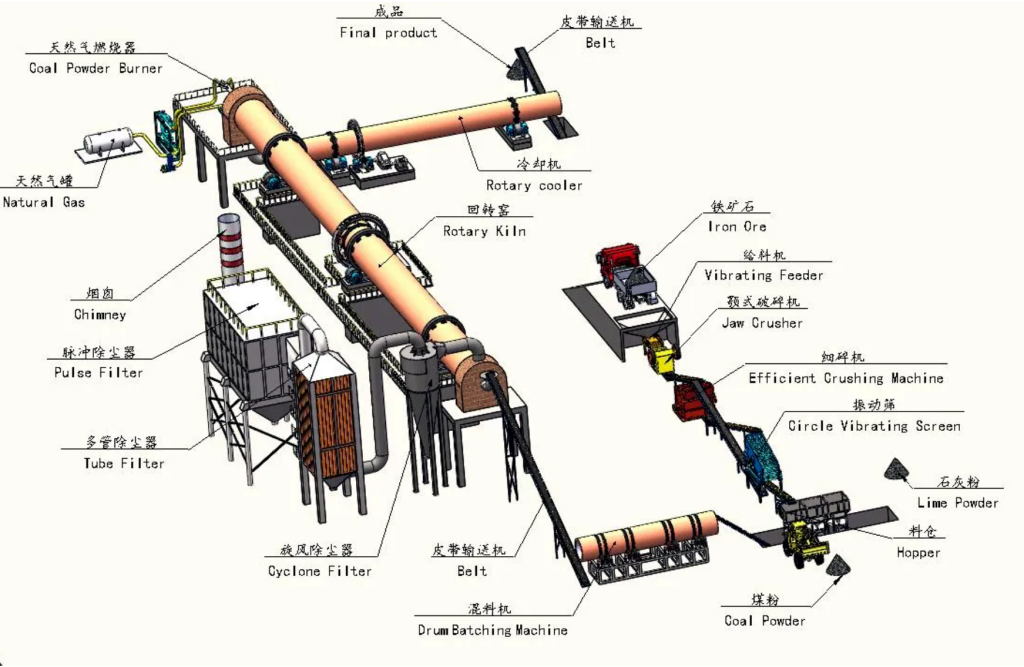

Zhongya Machinery’s sponge iron rotary kiln production line is a large-scale facility utilising pulverised coal and iron ore to produce sponge iron. This automated production line continuously transforms raw materials into high-quality feedstock for electric arc furnace steelmaking, characterised by substantial output, mature technology, and environmentally sound, high-efficiency operation.

Zhongya Machinery, as a renowned domestic mining equipment manufacturer, provides sponge iron rotary kiln production line solutions celebrated for their mature technology, stable operation, and high efficiency with environmental benefits. This production line integrates raw material processing, direct reduction, finished product cooling and separation, along with full-line automated control, serving as the core raw material preparation unit for short-process steelmaking.

The sponge iron rotary kiln production line core lies in coal-based direct reduction technology. Within the rotary kiln, the core equipment, iron ore is thoroughly mixed with the reducing agent (coal powder). Under high temperatures (1050°C–1100°C) and a controlled atmosphere, a reduction reaction occurs, removing oxygen from the iron ore to produce porous sponge iron with a high metallisation rate. This process essentially reduces iron from its oxide state to metallic iron without melting.

1. Iron Ore Beneficiation:

The iron ore first enters a jaw crusher for coarse crushing, then proceeds to a fine jaw crusher for further reduction. It is subsequently processed in a sand-making machine before being ground in a ball mill. After classification by a classifier, the material undergoes rough, concentrate, and scavenger separation through three magnetic separators to produce iron concentrate powder.

2. Blending, Mixing and Pelletising:

Iron powder, coke powder, ethylene glycol and other components are uniformly blended in specified proportions. The mixture is then fed into a disc pelletiser for pellet formation. The output material passes through a trommel screen; qualified pellets proceed to the rotary kiln, while oversize material returns to the pelletiser.

3. High-Temperature Calcination and Reduction:

Qualified pellets enter the tail end of the sponge iron rotary kiln. Within the kiln, pellets undergo calcination at 900-1100°C. Through the action of the reducing agent (coke powder), iron oxide undergoes a chemical transformation from high-valent to low-valent iron oxide, ultimately forming elemental iron. The sponge-like metallic iron leaves the kiln head and enters a cooler for temperature reduction to produce the finished sponge iron.

4. Exhaust Gas Dust Removal System:

Exhaust gases leave the kiln tail and enter a double cyclone dust collector for cooling and dust removal. They then pass through a multi-tube cooler for further temperature reduction before entering a dust collector for dust removal. The exhaust gases subsequently enter a double spray tower for scrubbing, meeting environmental emission requirements.

whatsApp

whatsApp