The CIL (carbon-in-leach) process used in gold production is a gold extraction technology that simultaneously performs cyanide leaching and activated carbon adsorption.

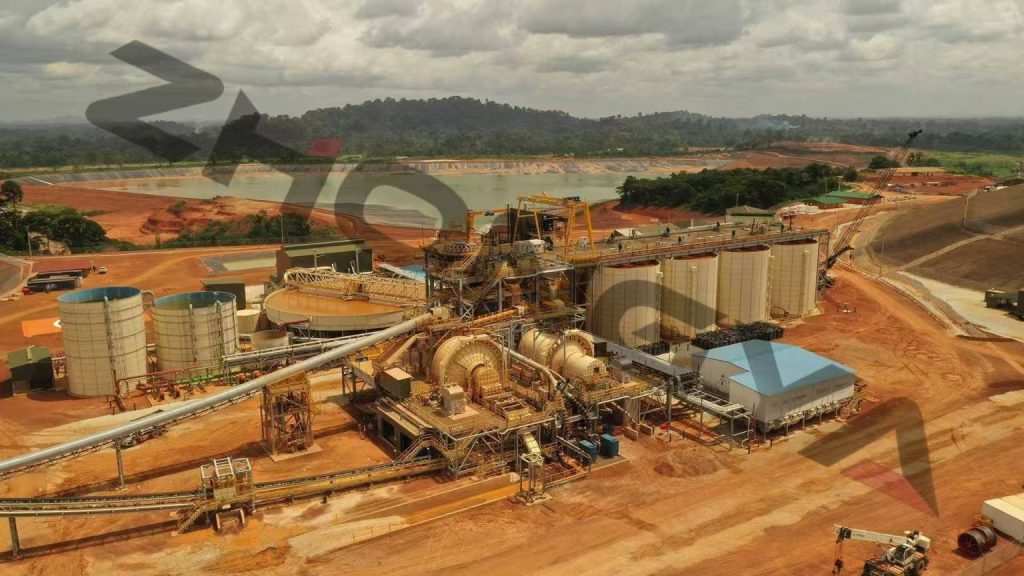

Gold CIL(Carbon in Leach) Production Line is a gold extraction process that combines cyanide leaching with activated carbon adsorption, and is suitable for treating gold-bearing sulfide ores or complex ores. This method synchronizes leaching and adsorption, shortening the process duration while boosting gold recovery rates.

Coarse Crushing: Jaw Crusher crushes the raw ore to <150mm.

Fine Crushing: Cone Crusher + High Pressure Roller Mill crushes the ore to <25mm.

Ultra-fine Grinding: Closed circuit of Ball Mill and Cyclone produces a slurry with a P80=75μm (200 mesh) to ensure the full dissociation of gold.

The crushing/milling circuit discharges its slurry into nine stepped high-efficiency cyanide leach tanks. The first two leach tanks carry out cyanidation of the gold slurry, while the last six or seven leach tanks carry out counter-current adsorption operations (cyanidation and activated carbon addition at the same time).

In the step of adding activated carbon, coconut shell activated carbon (small pore size, high activity, wear-resistant and renewable) is added to the slurry. According to the characteristics of gold and silver adsorption, coconut shell activated carbon can dissolve and adsorb gold and silver ions to form gold-carrying carbon.

Vibrating screen and dewatering screen are the key equipments for reverse movement of slurry and carbon. The filter press and high-frequency dewatering screen researched and developed by Central Asia can effectively reduce the wear and tear of carbon on the surface of vibrating screen and in the process of continuous pumping of slurry, reduce the cost, and facilitate the maintenance and operation.

The desorption electrolysis system is to carry out high-temperature desorption and electrolysis of gold in the gold-carrying charcoal through the mix of sodium cyanide and sodium hydroxide, and after the removal of wood chips and other sundries through the washer, it is used to carry out gold desorption using high-temperature high-pressure desorption method (150 degrees Celsius, 0.5 Mpa) for the desorption of gold, 99% of the gold can be dissolved within 2-6 hours.

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp