Capacity: 100-150 tonnes/hour (limestone, lapis lazuli and other soft rocks)

Feed size: ≤1000mm (can handle large soft rocks)

Discharge size: 0-3mm (fine sand), 3-10mm, 10-20mm, 20-40mm (adjustable)

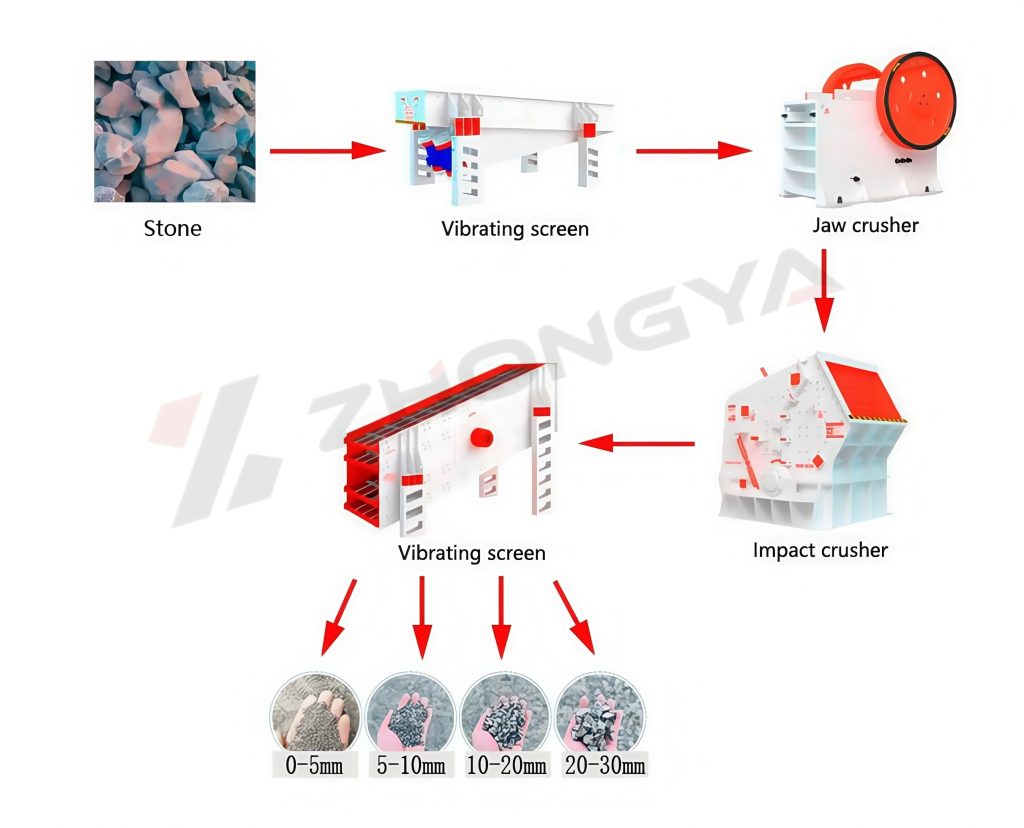

This 100~150 tph Soft Stone Crusher Plant is equipped with hopper, vibrating feeder, jaw crusher, impact crusher, vibrating screen and belt conveyor. It is mainly used for producing soft rocks such as limestone, gypsum, shale, etc. Coarse aggregate is usually used for ready-mixed concrete and asphalt concrete. Crushed material is used for road base and subbase. Fine aggregate is used for producing concrete and plaster.

Raw material dump into the hopper by loader forklift, then feed into jaw crusher evenly and continuously by vibrating feeder for primary crushing.

Then the coarsely crushed materials are conveyed to secondary crusher (according to material hardness and output sizes request),secondary crusher can choose impact crusher, CS cone crusher, HP multi cylinders cone crusher and single cylinder cone crusher.

The final crushed material goes to vibrating screen to classify final qualified products according to different size ranges as stock pile forsale, or for road builidng use. Unqualified materials will be carried back to the stone crushing equipment for recrushing.

Customer can classify final products according to different size ranges. All the final products are up to the related standards within and beyond China. Dust is generated during the working process while the dust control units are needed.

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp