Symons cone crusher is also called compound stone cone crusher.Compound cone crusher as the second crushing process, widely used in medium crushing, fine crushing operations

Application areas:

Mining, building materials, transport, energy, chemical and other industries.

Application materials:

Medium and fine crushing of iron ore, gold ore, non-ferrous metal ore, granite, quartzite, basalt and other hard rocks.

Symons cone crusher is also called compound stone cone crusher. Compound Cone Crusher has a very wide range of applications, mainly used for secondary medium crushing and tertiary fine crushing in metal mines and sand and gravel aggregate processing, suitable for crushing hard and medium-hard ores and rocks, such as iron ore, copper ore, limestone, quartz, granite, basalt and so on. It adopts the best combination of crushing frequency and eccentric distance, which makes the material to be crushed more finely crushed, and the crushing capacity has higher output compared with similar models, and also enhances the laminar crushing effect between the materials, which effectively improves the three-dimensional shape of the material after crushing.

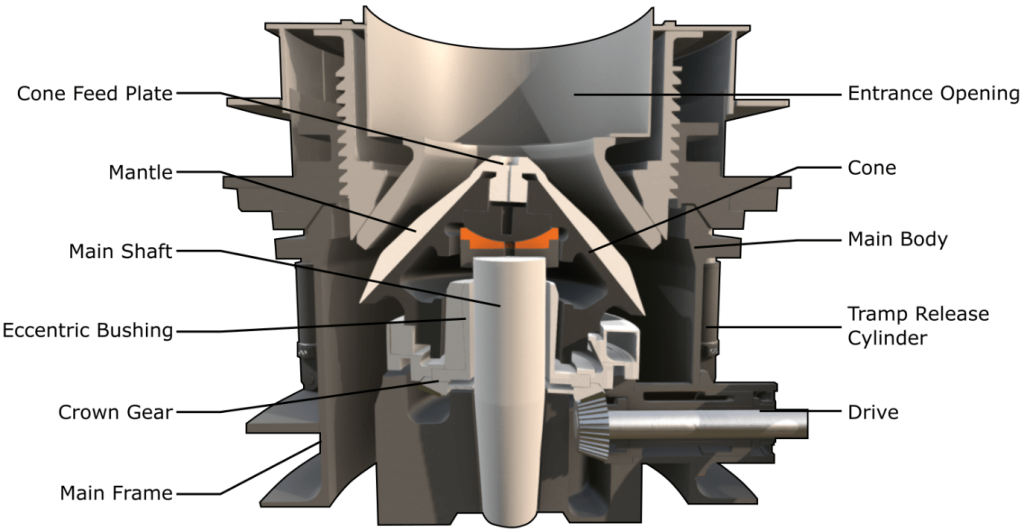

The structure of the compound cone crusher mainly consists of frame, fixed cone, moving cone assembly, spring mechanism, shaft frame, and transmission device. An electric motor drives the interlocking gear mechanism, while the transmission shaft and gear rotate the eccentric sleeve. The moving cone of the composite cone crusher rotates under the action of the eccentric sleeve. The moving cone and the fixed cone approach or separate from each other to impact and crush the material.

| Model | Moving Cone Diameter(mm) | Cavity Type | Adjusting Range of Discharge Opening(mm) | Max feeding size (mm) | Capaticy(t/h) | Motor Power(KW) |

| CS75 | 900(3') | Coarse | 25-38 | 150 | 59-163 | 75 |

| CS75 | 900(3') | Medium | 13-38 | 85 | 45-91 | 75 |

| CS75 | 900(3') | Fine | 6-22 | 35 | 27-90 | 75 |

| CS110 | 1200(4') | Coarse | 15-50 | 180 | 110-250 | 110 |

| CS110 | 1200(4') | Medium | 10-38 | 130 | 80-180 | 110 |

| CS110 | 1200(4') | Fine | 10-31 | 90 | 63-140 | 110 |

| CS160 | 1295(4 1/4') | Coarse | 19-50 | 205 | 172-349 | 160 |

| CS160 | 1295(4 1/4') | Medium | 16-38 | 178 | 132-253 | 160 |

| CS160 | 1295(4 1/4') | Fine | 13-31 | 115 | 109-181 | 160 |

| CS220 | 1400(4 1/2') | Coarse | 30-60 | 235 | 210-530 | 220 |

| CS220 | 1400(4 1/2') | Medium | 22-45 | 180 | 180-475 | 220 |

| CS220 | 1400(4 1/2') | Fine | 19-40 | 100 | 130-260 | 220 |

| CS250 | 1650(5 1/2') | Coarse | 30-60 | 228 | 299-635 | 250 |

| CS250 | 1650(5 1/2') | Medium | 25-50 | 205 | 258-417 | 250 |

| CS250 | 1650(5 1/2') | Fine | 20-45 | 178 | 181-327 | 250 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp